As a petrolhead, when approached with the above question, Some would probably be thinking, “That’s easy! Diesel gives Torque and Petrol lends speed. Diesel is heavy and slow and petrol is sleek and fast. Plus or minus a few points. Well, there’s the answer”

And there are the others who don’t feel content no matter how good their answer is.

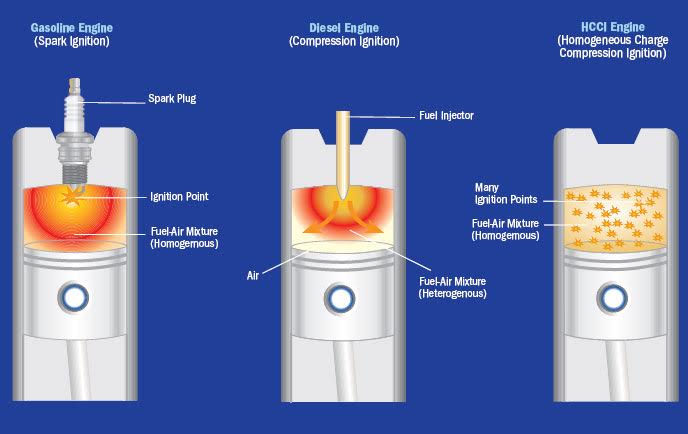

For once, I put myself in the latter’s shoes, and dug a little deep into the topic. The very notion of referring to I.C. engines as petrol and diesel is considered less technical. From now and on, it will be referred to as the S.I. (Spark ignition) and C.I. (Compression ignition) engines. A typical S.I engine makes use of Petrol as its fuel, Thermodynamically speaking, its working fluid. On the other hand, C.I engines work by combustion of Diesel. Now, that we’ve got the necessary basics cleared. Lets dive in. The first parameter we’ll be differentiating by is the Flame propagation.

This particular article will differentiate the engines based on the manner in which the flame propagates or travels within the combustion chamber once combustion has begun.

FLAME PROPAGATION:

S.I Engine:

Before delving into it, let’s have another basics recap. Any I.C engine has a power stroke in the process which provides the pressure rise to push the piston down. But what exactly is causing the pressure rise? It would be the combustion of the air fuel mixture within the combustion chamber. Now, that the above mentioned has been made clear, lets see what is the functional element that brings about the combustion. In case of the S.I engine, the combustion of the air fuel mixture at the end of the compression stroke, is initiated by the sparking of a spark plug. This spark starts the chemical process of combustion and something called a flame front is generated. A flame front is the thin zone of combustion which is the result of burning of fuel along with oxygen at very high temperature ranges. A flame front can be imagined to be a thin arc of flame travelling through the air fuel mixture and the flame survives and propagates by burning all “burnable” particles in the mixture with the help of the oxygen available in the “air” of the air-fuel mixture.

The way in which these flame propagates, the time it takes to burn the whole lot, the rate at which travels and a lot more makes the S.I engine different from that of the C.I engine.

The flame propagation in an S.I engine is called DEFLAGRATION. To know what is deflagration, let us go back and look at flame front in a different way. Instead of visualizing a flame front as an entity travelling through the mixture, let us consider the flame front as the burning of the all the particles in a thin arc and somehow, once the burning of that line of particles, the flame is transmitted to the next line of particles. Now, in deflagration, the combustion from line of particles to the other is uniform and the flame propagation is brought about by HEAT TRANSFER. i.e. The burning of the preceding set of particles will lead to heat release and hence rise in temperature, enough to initiate the combustion of the next set of particles. It should also be noted that in an ideal scenario, only when the combustion of ALL the particles in a particular arc takes place, the required heat is generated and the required temp rise is achieved to bring about the combustion of the next set of particles. This means, ideally, that there is a high chance of complete combustion of the particles. Also, since the flame front burns completely and steadily, the speed of the flame front is subsonic, in a S.I engine. It is estimated that they travel at around 100m/s. Also since there is steady propagation, the possibility of over pressure is very less. However, all the observations made above are for an “ideal scenario”.

In reality, lot of factors prevent complete combustion, like octane rating etc. This leads to incomplete combustion and also knocking. We’ll see about knocking in another write up for the very concept itself is large. In reality, due to umpteen factors, what happens is that the required heat build up and transfer from one line of particles to the other takes place even before all the particles of the preceding line is exhausted. This leaves behind a chunk of fuel particles left unburnt leading to emission problems through release of CO.

*HCCI Engines: Homogeneous charge compression ignition engines are highly efficient homogeneous charge engines in which ignition is due to high compression

C.I Engine:

Before getting into the mode of flame propagation in C.I engine, let us make some analogies. The deflagrating way of combustion can be considered analogous to streamlined fluid flow. Just like how in streamlined flow where the flow of particles is along a set of fixed stream lines, deflagration also takes place by combustion of articles along fixed arcs in the form of flame fronts. But, In case of C.I engines, there is a slight inclination towards the turbulent way of fuel burning. Also the combustion happens at 4 stages and the propagation at these stages varies. Unlike S.I engines, where there is a homogeneous mixture, In C.I engines, the injection of the fuel happens over a period of time. The Whole combustion process happens in 4 stages:

1. Ignition delay

2. Uncontrolled combustion

3. Controlled combustion

4. After burning

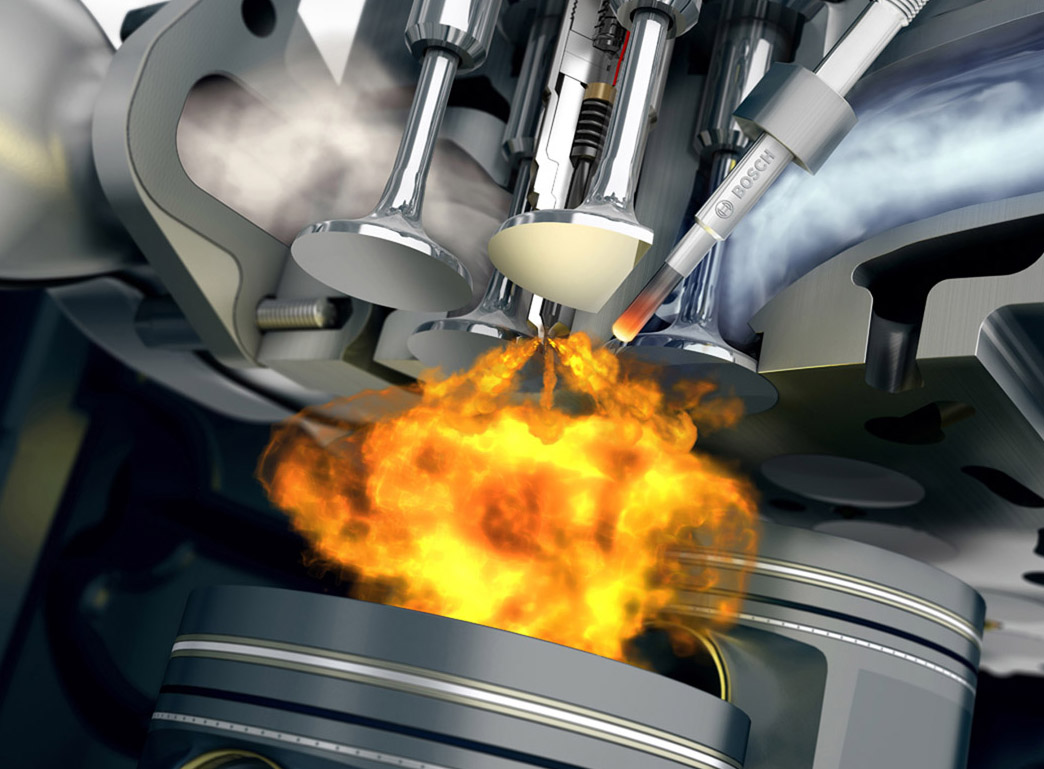

Flame as such originates and spreads only during the middle two stages. Before looking into it, let us clear out some basics again. In C.I engines, during the suction stroke the air alone is taken in and the fuel is injected over a period of time at the end of the compression stroke. The ignition takes place when the temperature of the air is increased to the level of self ignition temperature of diesel due to pressure build up. When the fuel combustion takes place, it happens so, not at a particular point but at several locations resulting in multiple flame fronts. Now, initially these flame fronts expand simultaneously in a rather rigorous manner resulting in sudden rise in pressure. This phase is the uncontrolled combustion phase. During this, the flame propagation is very turbulent and complete combustion is a rarity. It so happens that the multiple flame fronts collide with each other and cause pressure peaks at those points rendering the components damaged.

The next stage of combustion starts towards the end of the injection, and tends to be more “controlled” in nature. This is mainly because most of the fuel pockets have already been exhausted and the probability of multiple flame fronts in diminished. Now, the flame propagation inclines towards the streamlined manner.

Since it is clear now that, incomplete combustion and pressure surges happen in both the engines, how differently does KNOCK occur in either of the engines? To know more,

STAY TUNED for the next write up.

*This article is part of the The Basics: Diesel vs Petrol Series.

Leave a comment